Property Managers Discover 7 Benefits of Pressure Washing

Gutter Guards Protect Your Home

Pressure washing may be the most overlooked tool property managers have at their disposal for cutting the operational cost of their buildings and improving their overall appeal. Most property managers do not know the benefits of pressure washing a building, so they consider it a luxury.

Property managers seek to solve many of the problems by repainting a building or giving it a general facelift can be solved by pressure washing it. When placed side-by-side with the other methods property managers often use, the benefits of pressure washing are more significant.

There is no quicker and more environmentally-friendly method for ensuring the cleanliness and attractiveness of a property than pressure washing it. The reason is simple; pressure washing combines high pressure with the well-known power of water as a universal solvent.

These qualities give pressure washing the ability to dislodge dust, grime, chemical agents, and organisms that have ingrained themselves into the surfaces of a building for a long time. Pressure washing stops the unseen processes that hasten the deterioration of materials.

Property managers often need to see the benefit of pressure washing a building because they underestimate the power of dirt to harm the structure of their building. They don’t know how much harm the bacteria that have established themselves on the surfaces are doing.

As a result, they also don’t see the value of pressure washing for dealing with those problems. Pressure washing removes harmful materials from the surfaces of a building; it does it in record time and at a lower cost than the cost of fixing or repainting the building.

If you’re a property manager looking for efficient ways to improve the appearance and performance of your managed properties, what are the benefits of pressure washing for your business? This post explains the reasons to make pressure washing part of your building maintenance arsenal.

7 Benefits of Pressure Washing for Property Managers

Number 1: Attract new customers and residents

Whether you manage a residential or commercial property, pressure washing can help your business. Property managers are always advertising, but there is no better advertisement for your business than the appearance of the building.

Buildings that are grime-free by periodic pressure washing will not have unsightly surfaces that repel visitors. People who live in them are less likely to complain and more likely to renew their leases. Businesses domiciled on the premises can attract more clients because customers feel at home inside the building. As the property manager, you can entice new residents or businesses to lease from you.

Number 1: Attract new customers and residents

Whether you manage a residential or commercial property, pressure washing can help your business. Property managers are always advertising, but there is no better advertisement for your business than the appearance of the building.

Buildings that are grime-free by periodic pressure washing will not have unsightly surfaces that repel visitors. People who live in them are less likely to complain and more likely to renew their leases. Businesses domiciled on the premises can attract more clients because customers feel at home inside the building. As the property manager, you can entice new residents or businesses to lease from you.

Number 2: Improved property values

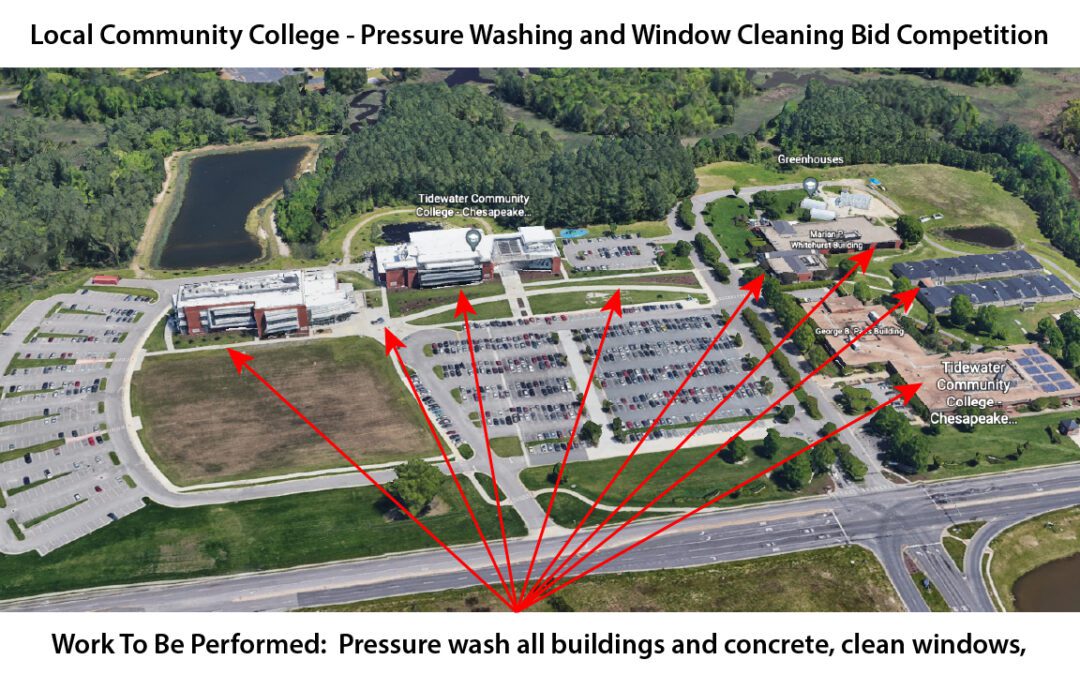

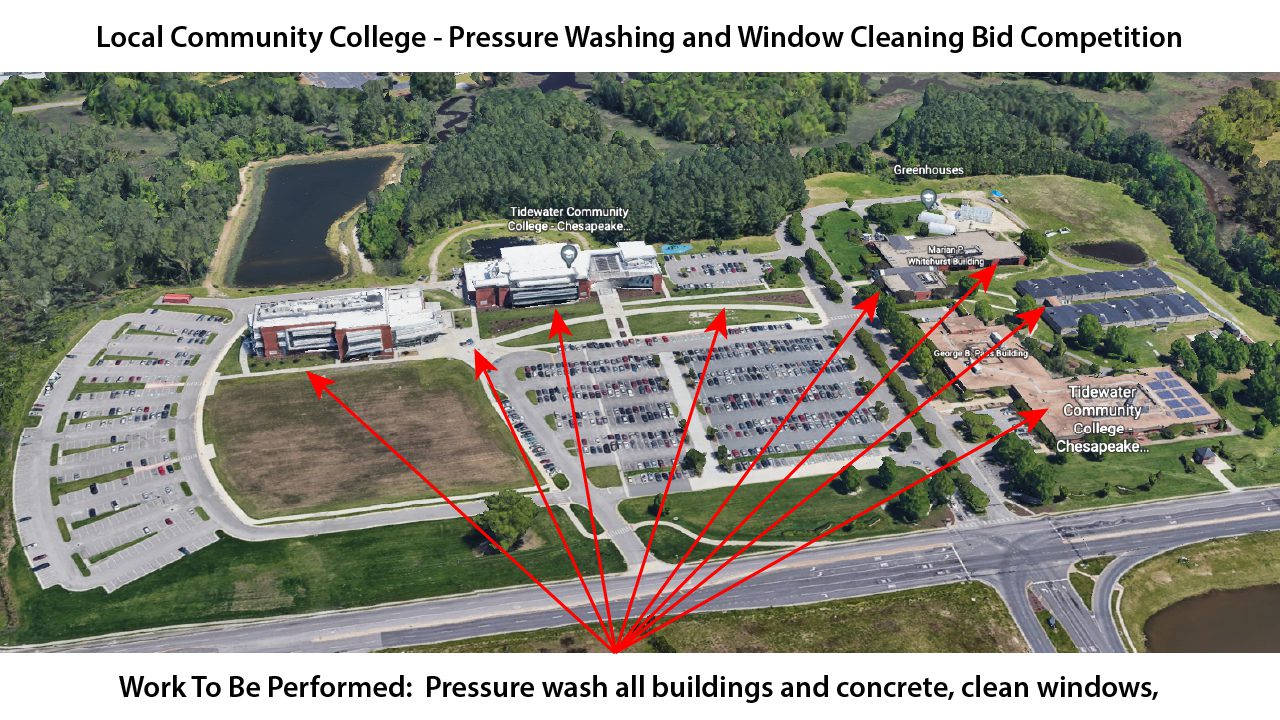

A significant benefit of pressure washing is that you can instantly restore the appearance of different types of surfaces. Driveways, parking lots, walkways, lobbies, patios, roofs, sidings, and fences are a few of the areas you can clean with pressure washing. Interestingly, these are some essential features of a building’s curb appeal.

Algae, mold, and mildew are common sights on buildings, especially after the summer rains, due to high heat and humidity. These growths can have a marked impact on a property’s value and the overall attractiveness of a neighborhood. But it is easy to maintain or even boost the value of your properties and raise the rental rate if you pressure wash the building regularly.

Number 3: Good for preventative maintenance.

The best way to maintain your property is not to stay up to speed with the problems. The best way is to minimize maintenance issues in the building. This is preventative maintenance: taking steps to solve problems early so they do not become costly maintenance items later.

Mildew, mold, grime, hazardous chemicals, bacteria, and mold accelerate wear and tear on the materials of the building. Mold, in particular, penetrates surfaces to extract the substrates from materials. Over time, this compromises the structural integrity of sidings, concrete surfaces, roof shingles, and other mold-infested surfaces. Pressure washing surfaces helps get rid of harmful substances and organisms that do damage to your building.

Number 4: Property managers can save and make more money.

For example, the cost of fixing damage caused by the acid in bird droppings on the metal surfaces of your building, such as gutters and drainage systems, pales compared to the cost of pressure washing those surfaces to protect them. This is just one way pressure washing your building saves you money.

Beyond saving money, pressure washing will help you make more money. One benefit of pressure washing is the improved ambiance of the building, which means you can attract quality clients who can afford to pay higher rents. Additionally, you can cut vacancy rates by getting existing tenants to stay.

Number 5: Pressure washing improves health.

One of the least-talked-about benefits of pressure washing is its impact on the health of the people who live in or work in a building and those who visit the premises. Allergies, asthma, and other respiratory problems are enormous problems in the enclosed internal environments of facilities. Allergens and irritants get circulated in and out of the closed HVAC system, but pressure washing parts of the building can help eliminate them. Pressure washing will remove mold, mold spores, pollen, dust, and bacteria, thus improving the indoor air quality of your buildings.

Number 6: Pressure washing is environmentally friendly

The main things you need to pressure wash a building are high-pressure water with pressure washing solutions that are EPA-certified and primarily biodegradable. No toxic chemicals are used in this process. So, there is no chance that people will get sick after pressure-washing the building.

Pressure washing will not leach harmful chemicals into the soil or groundwater. There is no risk that some of the solutions used in the process will find their way into the drinking water and harm nature or people. Unlike cleaning methods that use harsh chemicals, pressure washing is one of the most environmentally friendly cleaning methods.

Number 7: Helpful in maintaining common areas

The final benefit of pressure washing for property managers is its value in maintaining the common areas of a community. Common areas play a role in tenants’ happiness and are vital for attracting new renters to your community.

Keeping common areas, such as pool areas and lobbies, clean and sanitary can be a considerable challenge. Common areas are the public face of your community, and pressure washing them is a great way to keep these highly visible parts of the property clean, safe, and attractive.